Automating Flat Glass Machining

Bavelloni, historical Italian brand in the field of glass processing, has entered into a partnership with Pneumax to automate its lines of straight-line and double edging machines. The pneumatic components used in these machines provide considerable advantages, both in terms of performance of the functional group and in terms of item management, which in this way is extremely lean.

Bavelloni is a brand that made the history of flat glass grinding equipment. Today it is a completely Italian Company with 100% made in Italy products.

Product portfolio for flat glass grinding operations comprises straight-line and double edging machines, bevelling machines, working centers, cutting tables as well as drilling/milling machines Today Bavelloni, is able to meet the most diverse processing needs, starting from small standard and stand-alone machines, to large fully automated plants.

A partnership focusing on innovation

The partnership with Pneumax stems from the need to have both a complete range of standard pneumatic components and a customization service that can enhance specific applications. It is fundamental, in fact, that the relationship with strategic suppliers is not limited to the supply of components, but also promotes a constant dialogue on the application. The Bavelloni lines use components ranging from valve islands to proportional technology, air treatment and vacuum technology. The quality and reliability of the machines must be guaranteed by analysing and optimizing every single component and acting on all parameters, from operating performance, to weight, to compact and “clean” design. Often this implies the need to realize customized solutions. The Bavelloni lines are designed to allow customers an integrated management, where even the subsystems are interconnected: this is the reason why the choice of suppliers is fundamental. These are the requirements that have led to Pneumax being identified as the ideal partner, in addition to the fact that it is an Italian company: a “showcase” for the made in Italy that represents excellence in this sector worldwide.

The application: double-edging line with robotized loading station

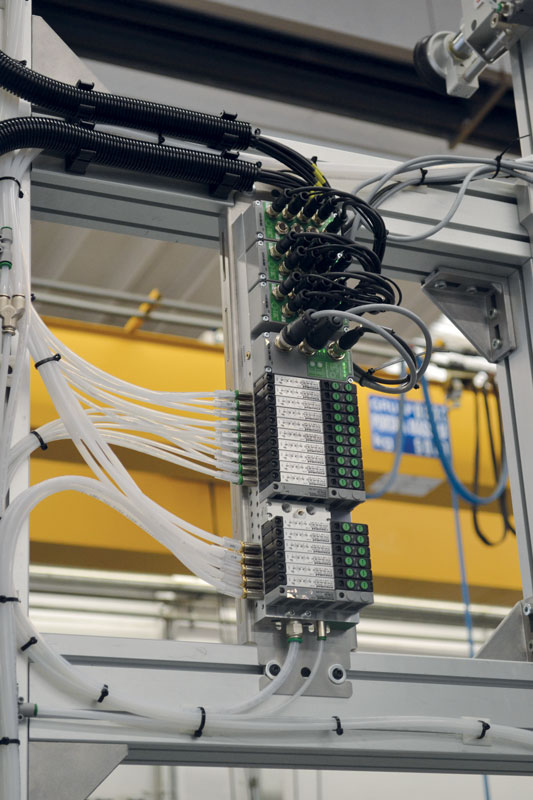

The solution adopted concerns the complete automation of the grinding process of the 4 edges of the slabs, with the possibility of multiple finishes; glossy, matt, with or without bevels and so on. The most complex part was the loading station, the real brain of the plant, where the data of the company ERP converge. The loading station manages the correct feeding of the plant as well as well as the tooling of the entire downstream line. Here you will find an anthropomorphic robot equipped with a suction cup gripping frame. The adaptation to the innumerable variety of sizes of the slabs to be processed required the use of a very advanced pneumatic system. Moreover, the need to feed a large quantity of suction cups for the most diverse operations, required the installation of a valve pack of the smallest possible size and weight. Another requirement was to use the manifold also from a central location for the confluence of all sensor systems applied to the gripping frame, in order to minimize the pneumatic/electrical equipment hooked to the robot arms. Pneumax 3000 series solenoid valve batteries were chosen to meet these requirements.

The application: straight line edging line with robotized transfer station

The solution adopted allows to minimize the human intervention for the process of grinding on 4 sides of glass slabs. Two grinding machines are used to process one side at a time. The loading/unloading area is attended by the operator, while the transfer and rotation of the slab from one grinding machine to the other is performed by an anthropomorphic robot equipped with suction cup frame. Like the previous line, this one must process glass slabs that, from the minimum to the maximum size, have a potentially infinite dimensional variation; therefore, maximum flexibility in handling the suction cups of the gripper case is required. In these two very different solutions, pneumatic components have been used, obtaining considerable advantages, both in terms of performance of the functional group and in terms of item management, which in this way is extremely lean.