State-of-the-art Test Bench for an Increasingly Connected Company

The partnership between Hydro+Power and Bosch Rexroth has led to the construction of the new BCI 1000ES impulse test bench, a project in line with the renewal of the production layout in Industry 4.0 and Connected Hydraulics logic. The Bosch Rexroth 4WRLE proportional valve, used to control the pressure wave, is its beating heart.

by Silvia Crespi

The Hydro+Power brand was born from the synergy between O+P, a company specializing in equipment for hydraulic pipelines with a product portfolio of more than 120 items, and Brescia Hydropower, well nown manufacturer and service provider for hydraulic systems.

Hydro+Power’s main activity concerns the design and construction of testing systems, which can be used both for laboratory tests and for the testing of production lines. The company’s core business is the production of test benches for components used for the filtration of liquids, hydraulic and mechanical components.

Modernising the impulse benches and the entire production process

In order to meet market needs, Hydro+Power is committed to pursuing a number of goals: to increase the performance of its machines, to make its impulse benches more efficient, to follow a green approach to production and, finally, to improve the production process at company level. The company turned to Bosch Rexroth to meet these challenges.

“The cooperation with Bosch Rexroth starts from afar – explained Emiliano Portieri, Hydro+Power Sales & Project Manager -.

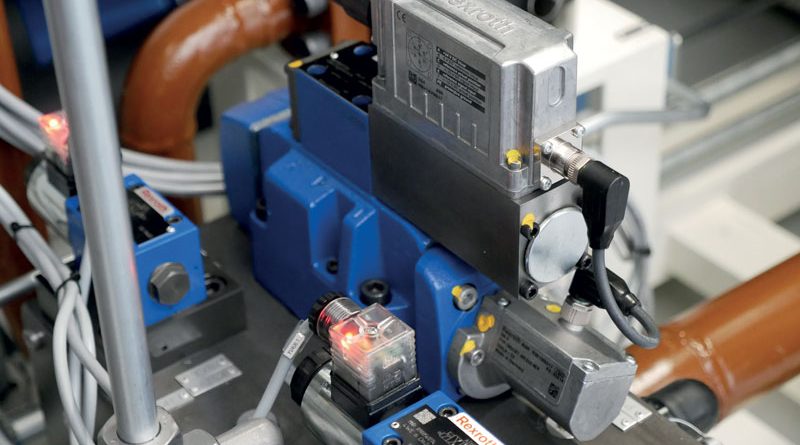

Hydro+Power has always relied on the quality of Rexroth products, thanks to its extensive portfolio and the close support of its specialists. It is a valid partner that supports you right from the design phase, it is a comfort, a reassurance, a confirmation and a guarantee to get to the bottom of the objectives”. “The BCI 1000ES impulse test bench is the result of this synergy” – explains Riccardo Patat, Sales Product Manager Industrial Hydraulics at Bosch Rexroth – and the 4WRLE proportional valve, used to control the desired pressure wave, is its beating heart. These types of machines are ready for Industry 4.0 and seamlessly integrate into the customer’s production layout, allowing useful data to be recorded for predictive maintenance”.

Directional control valves, pilot-operated with integrated electronics

4WRLE directional control valves are pilot-operated, with electrical position feedback and integrated electronics (OB). Besides being extremely reliable, they feature a proven and robust design. Safety is guaranteed by the following features: the control spool of the pilot control valve is in the “fail safe” position when the unit is switched off, while the control spool of the main valve is in the spring centered central position and/or in the offset position. These high quality valves are extremely flexible as they are suitable for position, velocity and pressure control. Precision is due to their high response sensitivity and little hysteresis. IO-Link interface is available as optional.