Pneumatic Automation for Woodworking

Aireka, Stima’s brand which brings together different product lines in the field of pneumatic automation, developed targeted solutions for the woodworking sector: from pneumatic coolers to solve overheating problems in electrical panels, to air blades to clean parts or areas of the machine, up to nozzles to keep cameras and photocells clean and therefore efficient.

by Elena Magistretti

Aireka is a brand of Stima, a company operating since 1965 in the field of distribution of industrial automation products. The brand groups a series of products different from one another, but united by the fact that they represent simple and innovative solutions to complex problems, both from a technical standpoint and in terms of cost/benefit ratio. The simplicity of these solutions derives from the cleverness, knowledge and great experience of the designers who created them, with a constant attention to customers’ needs.

Overheating: a common problem in the wood industry

The issue of overheating of cabinets and electrical panels affects all industrial sectors. In the wood industry sector, another problem is added to this: dust and particles generated by the cutting of wood may get inside the control cabinet, depositing on the terminals and electrical components and potentially starting a fire. Aireka’s pneumatic coolers feed compressed air into the cabinet, creating a slight overpressure inside the cabinet and thus preventing the entrance of impurities.

Compressed air conditioners for electrical panels are a reliable, economical and easily installed solution for the thermal control of electrical panels and PLCs. As they have no parts subject to wear, they are totally maintenance-free and work perfectly at any ambient temperature. Using only compressed air, they allow cooling even over 1600 W.

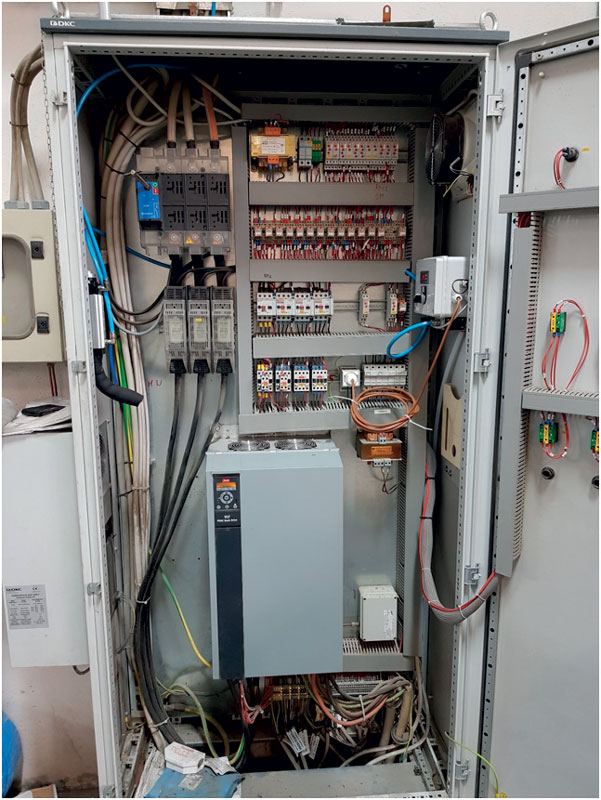

In an application developed for a customer operating in the field of woodworking, in particular in panel cutting, the line control inverter placed at the bottom generated serious overheating problems by blocking the line itself.

A pneumatic cooler was installed, visible on the left side of the image on this page, while on the right side you can see the control unit of the cooler. Once the pneumatic connections between the control unit and the cooler have been completed, the operator only needs to set the control unit to the two desired on/off values of the cooler, which will only remain in operation for as long as necessary to keep the temperature within the desired range.

Air blades to clean parts or areas of the machine

In the wood industry, there are many requirements for cleaning parts or areas of the machine, especially near cutting areas.

The ABT series air blades, with lengths ranging from 30 to 600 mm, are one of a kind. The high blowing power and precision which characterize them are obtained thanks to the double air flow on the central blade and the easy fixing by means of two neodymium magnets and brackets which allow the blade orientation according to the most varied needs. They represent the ideal solution for both cleaning and drying and cooling applications. For specific requirements, large air blades (even over 2,000 mm) may also be produced.

Patented nozzles to clean cameras and photocells

The same problems of dust contamination are particularly treacherous for cameras and photocells. If they are deposited on the photocell reading element, for example, impurities can generate incorrect readings and signals which may cause problems to machinery and thus to production.

Aireka’s patented UGR series nozzles are designed specifically to overcome these problems. They are screwed directly on the photocell and, using a very low supply pressure (about 0.2 bar), they blow air over the entire circumference of the photocell which is perfectly cleaned.

Aireka manufactures this type of nozzles for most photocells present on the market.