Planning Material Flow Solutions is Getting Simpler

Planning and designing material flow solutions is now much simpler thanks to Interroll Layouter. With this application, which can be seamlessly integrated into the AutoCAD design program, planners and system integrators can now visualize even complex conveyor systems end-to-end at the click of a mouse.

With the inclusion of the recently introduced flow storage and retrieval machines and transfer cars in its planning software, Interroll has expanded the range of applications of Interroll Layouter tool. With this application, which can be seamlessly integrated into the AutoCAD design program, planners and system integrators can now visualize even complex conveyor systems end-to-end at the click of a mouse and make them available for quotation and ordering processes.By digitalizing the necessary process chain, the effort required by customers is dramatically reduced – by up to 90 percent, depending on the initial situation.

An exhaustive visualization of the entire system

The ability to visualize technical planning has always been one of the central requirements in the project business with modern material flow solutions. But even today, the path from the first plant design to the detailed technical project planning, which leads to the preparation of a quotation and the concrete award of the contract, is in most cases still characterized by time-consuming breaks in the work processes.

For example, initial visualizations of the overall solution must later be broken down to all the required individual components of the desired plants.

With the help of the Layouter tool, this phase of the process is no more needed:planners and system integrators can visualize the planned conveyor solution based on the desired parameters. The Layouter also simultaneously specifies all the necessary technical components of the respective solution. In addition, the plug-and-play modularity of Interroll’s conveyor platforms ensures that the engineering effort required to put together the overall solution is eliminated.

The advantages of this approach are impressive: Already with his first design, the AutoCAD user has all the technical information for the desired conveyor solution and, in the case of special framework agreements, even the necessary price information. This means that the planning data can easily be reused for the subsequent quotation or ordering process.

The Interroll Layouter can be used for Interroll’s modular platform offers, such as the Modular Conveyor Platform (MCP), the MPP, or the company’s flow storage solutions. The free application is available as a plug-in for a full version of AutoCAD from version 2014. The Layouter is compatible with Windows 7 to Windows 10; Microsoft Excel is required on the workstation computer.

How to better organize and automate the ‘last mile’ in manufacturing areas

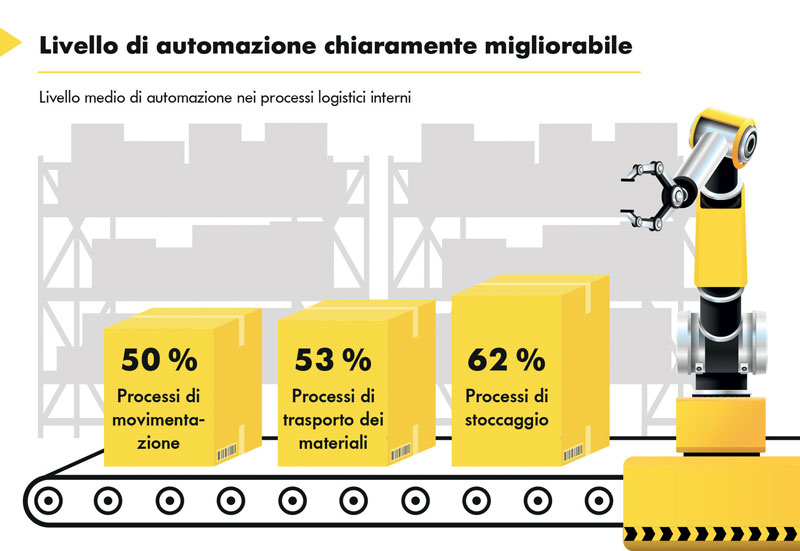

A survey commissioned by Interroll and conducted by the agency Faktenkontor (Hamburg), revealed that there is still a high demand for automated material flow systems in medium-sized German manufacturing companies.

Automation and robotics are key technologies for greater competitiveness, quality and sustainability in industrial production. In order to optimally tap the productivity potential of these technologies, the internal flow of materials plays a central role. This applies not only to the supply of materials to assembly lines or robots, but also to the most seamless connection of storage and picking areas with incoming and outgoing goods.

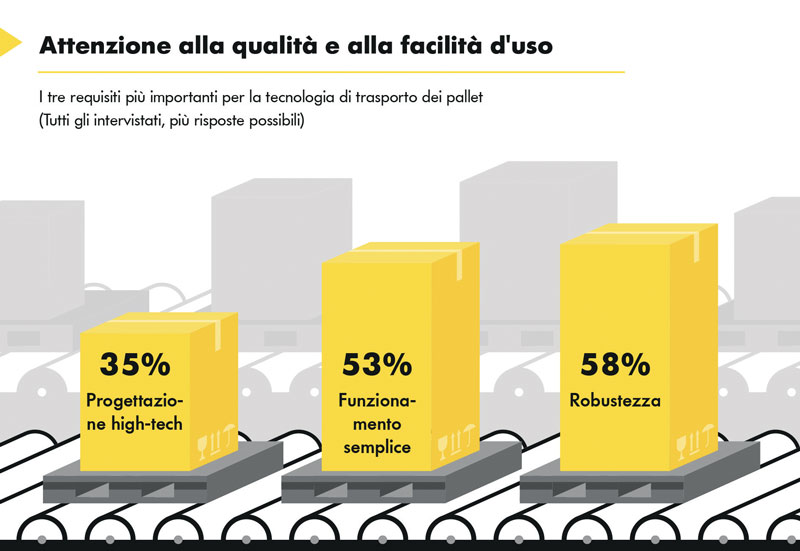

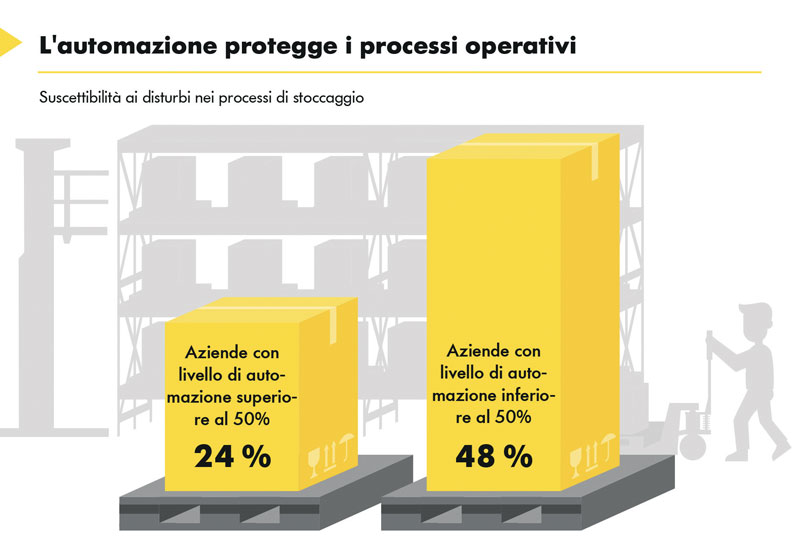

The average degree of automation of internal material handling at the companies surveyed is only 53 percent. Not even one in five companies (19 percent) achieves a level of automation of over 75 percent for these processes. A total of 200 production companies in Germany were surveyed. The focus was on companies with 50 to 500 employees and a turnover of up to 500 million euros. The companies came from a wide range of sectors, including mechanical engineering and the food and consumer goods industry. With the results of this survey in mind, Interroll is actively working on a new solution – the Smart Pallet Mover, or SPM- to better organize and automate the “last mile” in manufacturing areas. This new interface will improve the connection between the different phases of the material flow, that is, the movement, organization, input and output of pallets. The SPM can be deployed not only in proximity of manufacturing machines but also between different production cells within the same manufacturing process. The Infographics summarize the results of the survey.