Low Cost Magnetic Sensors for Linear and Angular Measurements

The magnetic sensors of the Ex and KSAx series have been developed by STEM to meet the most diverse needs of all those who need low cost sensors for linear or angular measurements. The Ex series, for linear measurements, is ideal for position control applications of hydraulic and pneumatic valves and distributors; while the KSAx series provides accurate angle measurements at high speeds thanks to fast data processing.

by Chiara Giaccherini

Over 30 years of activity Stem has developed hundreds of different types of sensors, in order to satisfy most of the customers’ requests. The main advantage of the magnetic sensor is that it allows measurement without contact with the moving part, it is therefore free of mechanical wear and therefore ensuring a high life cycle. To follow the continuous evolution of the products and to meet customers’ need to use low-cost sensors for linear and angular measurements, STEM offers two product families: Ex and KSAx sensors for angular measurements.

Excellent noise immunity and maximum repeatability

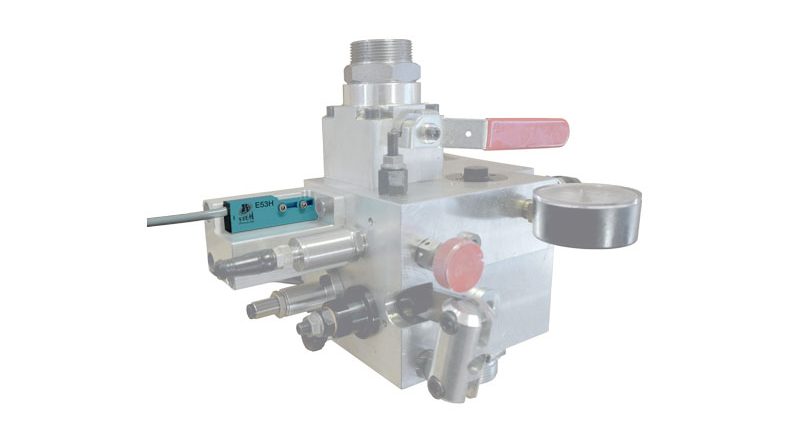

The Ex family of sensors (E53HLC, E57HLC, E740HLC and others) allows, by assembling a magnet on the moving part and keeping the sensor fixed, to measure with a good resolution (<1/10 mm) the linear displacement of the mechanical part. Depending on the type of sensor, the output can be current (4-20 mA) or voltage (0-10 V). In some models there is a completely digital signal conditioning chain that guarantees excellent noise immunity and excellent linearity of the measurement curve. The maximum measurable displacement is proportional to the size and type of magnet (such as ferrite, neodymium, alnico) as well as to the distance between the magnet and the sensor. Indicatively, the measurable displacement is less than 40 mm. This type of sensor finds its natural application for checking the position of hydraulic and pneumatic valves and distributors.

The E53HLC sensor, for example, has been used successfully on some hydraulic proportional valves used in the lift area. Through its measurement, the sensor provides feedback to the electronic control system to control the acceleration and deceleration curves of the lift cabin, improving the stopping accuracy on the floor.

Each sensor can be calibrated in order to guarantee maximum repeatability of the measurement according to the movement displacement and temperature of the system. STEM offers a support service both for the design phase and for the calibration of production batches according to customer specifications.

Configurable remotely and with different output types

The KSA family of sensors detects the absolute angular position of a rotating shaft. Fast data acquisition and processing provide accurate angular measurements at high speeds.

The sensors can reach a resolution of up to 12 bits with ½ degree accuracy and are available with different types of outputs: KSA01PW, PWM digital output (24V open-collector); KSA01SS, SSI digital output (5 V line-drive); KSA01IO, digital output on IO-link bus; KSA02AC: analogue output in 4-20 mA current; KSA02AV, analogue type voltage output 0-10 V. All sensors mentioned above have an input to configure the zero position and the angle increase direction. The IO-link version can also be configured remotely and can transmit useful information for predictive maintenance such as temperature or management of configurable limit positions. The analogue version is available with different angular excursions (100°, 180°, 360°) in order to maximize the sensor output dynamics according to the desired angular excursion.