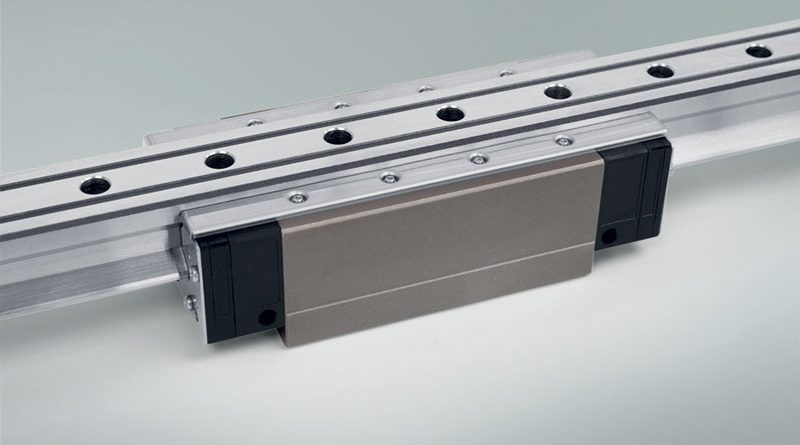

Linear roller guides

In the machine tool industry, roller guides often work in contaminated environments. Depending on the application, guides can be exposed to aluminium chips, metal particles and graphite dust. If these contaminants enter the interior of the slider, service life will be impaired. The guides themselves should be equipped with a highly effective seal, which is why NSK has optimised the roller guides of its RA series.

The sliders can now be equipped with high-performance V1 seals that reliably protect against contamination entering the recirculating roller area. Featuring a special profile and material with high abrasion resistance, the seals simultaneously provide effective sealing and, at the same time, low friction. In turn, the repeatable and accurate guidance of spindles, portals or slides in machine tools, is assured.

V1 seals are located at each end of the guide carriage. NSK also introduced a further seal on the underside of the guide carriage during the course of its optimisation work. This second seal prevents dirt from getting into the slider when passing through particle accumulations in the machine, for example. Since machine axes are often mounted upside down or at an angle, the improved lower seal makes a significant contribution to preventing contamination from entering the slider.

As an option, RA linear roller bearing and guideway assemblies can be ordered with sealing caps or a cover strip for the mounting holes – an ideal choice for contaminated environment

applications. A further option is the integration of the compact K1 lubrication unit into the carriage, thus ensuring permanent lubrication of the raceway.