It’s Only a Matter of Adjustment

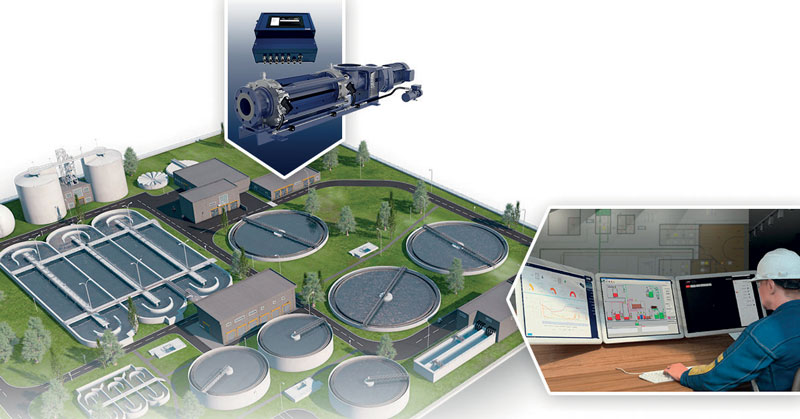

Seepex launches a fully automatically adjustable progressive cavity pump. The pump is automated for the best pumping efficiency: with SCT AutoAdjust it can be automatically adjusted to the optimal operating point: a good example of digitization of Seepex’s Smart Conveying Technology (SCT).

In the intelligent future of media pumping applications, many aspects will become easier. Pumping technology specialist Seepex launches a new generation pump automated for the best pumping capacity: a progressive cavity pump featuring automatically adjustable stator clamping.

With SCT AutoAdjust the progressive cavity pump is automatically adjusted to the optimal operating point – simply with one click from the control room or locally on site through the SEEPEX Pump Monitor via the app. The clamping between the most important conveying elements – rotor and stator – can be easily adapted to the conditions in the process or the degree of wear. With “SCT AutoAdjust”, Seepex has further developed and digitized its Smart Conveying Technology (SCT).

Top-quality pumping capabilities through the use of Industry 4.0 properties

being developed with integrated Industry 4.0 technology, SCT AutoAdjust is the bridge between the world of analog pumps and digital solutions.

One remote click or a touch on the on-site Pump Monitor is enough to adjust the stator clamping system in such a way that the pump always provides top-quality pumping performance. Seepex has been setting standards in the area of easy maintenance since 2008 with its predecessor, the mechanically adjustable SCT, and now offers the possibility of readjusting the stator clamping. This technology is now being revolutionized once more with the introduction of SCT AutoAdjust. Manual adjustment, for example in the event of wear or short-term process changes, is completely unnecessary here because the service technician responsible can easily carry out all the changes from the control room. In this new pump generation signals are transmitted via analog signal cables or digitally via various bus systems. Travel to and from the locations where work needs to be carried out is eliminated, thereby saving both time and labor costs. Even in complex plants, where pumps are often difficult to access, the service technician benefits from the remote adjustment option. Quick access to the pump on site is possible via the SEEPEX Pump monitor or via bluetooth and app via tablet. In this way the SCT AutoAdjust system can also be combined in no time at all with condition monitoring systems such as SEEPEX Connected Services.

Easy integration into existing process infrastructures

The control system, sensors and readjustment device are already included in the package. The SEEPEX Pump Monitor, which can be integrated on request, measures all relevant operational parameters such as temperature, flow rate, pressure, vibration, etc. – 365 days a year, 24 hours a day. This means that the data can be analyzed only locally or, even more extensively, also in the cloud, in the SEEPEX Connected Services. This makes it possible to measure and optimize pump performance. The degree of wear becomes apparent and any upcoming maintenance can be planned in advance. This reduces downtimes and avoids unplanned outages. Integration into existing process infrastructures could not be easier. Start-up, connection to the Pump Monitor and connection to the cloud are carried out by a SEEPEX specialist.

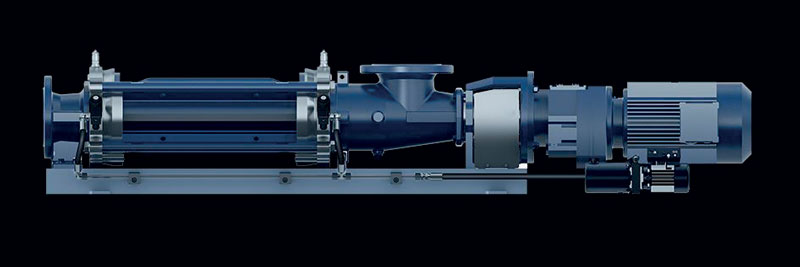

Fast and easy maintenance is ensured by Smart Conveying Technology

With its Smart Conveying Technology (SCT) Seepex revolutionized the maintenance of progressive cavity pumps. The tried and tested design principle: the Smart Stator consists of two halves and can be easily installed and uninstalled on site without having to remove suction or pressure pipes. Maintenance can therefore be carried out very easily by just one individual. With an integrated retensioning device, the clamping between the rotor and the stator can be adjusted for optimum conveyance if the flow rate changes, e.g. due to wear and tear. This significantly extends the service life of the rotor and stator, reduces the need for spare parts and lowers the life-cycle costs of SEEPEX pumps. With the SCT AutoAdjust this retensioning of the stator is now performed automatically at the push of a button via a hydraulic unit, completely without the use of special tools. The newly developed premium model range makes work on the pump considerably easier and therefore helps to save even more time and costs. In addition to the usual adjustment of the pump speed, retensioning is a further, much more efficient way of keeping the pump flow rate constant within the optimum range. Seepex enables maximum energy savings and a short, fast and easy maintenance.