Innovative Bearings for High Speed Rolling Mills

In order to obtain the highest production rates, today’s rolling mills handle heavier loads and faster speeds than ever before. The innovative 2TS-IMC and 2TSMA-IMC tapered roller bearings have been developed by Timken for rolling mill auxiliary equipment operating meet customers’ expectations: the internal geometry of the bearings’ rings and rollers are designed to reduce heat generation under these conditions.

by Sorin Tudor

The focus of this paper is on the rolling mill auxiliary equipment operated under high and very high-speed conditions in conjunction with the heavy loads. Bearings mounted on the input shafts of gear drives of cold and tube mill drive trains – and those mounted on the output shafts of reels of steel and aluminum cold mills – are the ones most often exposed to high or very high speeds.

Bearings from the input shafts of gear drives operate under high speed mainly due to the high rotational speed coming from the electrical motor, while those from the output shafts of reels operate under high speed mainly due to their very large inner ring bore diameter.

The Timken Company provides a complete range of solutions for rolling mill auxiliary equipment, comprising: bearings (ball, tapered, cylindrical and spherical); bearing-related products (housing units, lubrication and seals); power transmission equipment (couplings, gears, belts and chains); services (bearing inspection and repair, condition monitoring systems).

Timken solutions help assure consistent operation for auxiliary equipment. The innovative tapered roller bearing construction of the 2TS-IMC and 2TSMA-IMC has been developed by Timken for very high-speed operating conditions.

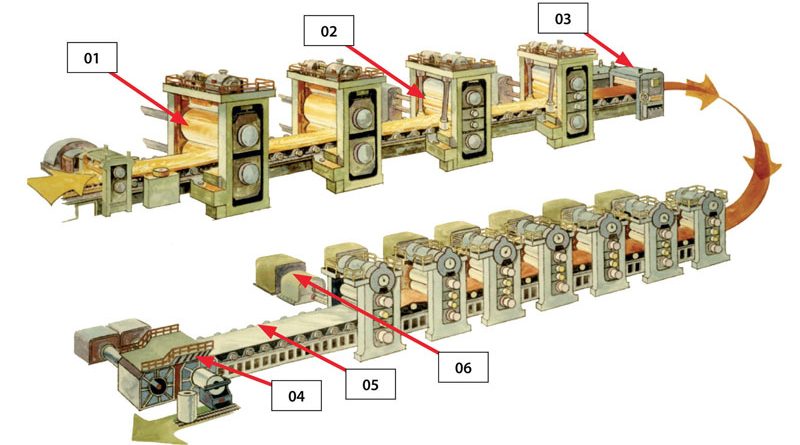

The mill drive train

The mill drive train supplies mechanical energy to the top- and bottom-driven rollers of the rolling mill stand. The mill drive train is configured with an electrical motor, a gear drive (Figure 2) and a pinion stand, all connected by couplings.

The electrical motor generally covers a power range of 500 kW to 15 MW and has an angular rotational speed of 1500 rpm or more. The motor torque, measured in kNm, is tailored to meet the rolling mill’s operational requirements.

The gear drive’s role is to increase the torque provided by the electrical motor simultaneously with the decrease in the rotational speed. Motor torque increases with the gear ratio from the input to the output shaft. Angular rotational speed decreases with the gear ratio from input to output. The power remains approximately constant on all gear drive shafts, reduced only by the gear drive’s efficiency from input to output.

There is tremendous variety among rolling mill gearbox configurations, including single, double and triple reduction. Despite the variations, all these gear drives are considered heavy-duty load and are designed for high reliability, with a typical bearing target L10 life of 50,000 hours or more.

The pinion stand splits the gear drive’s output power in two for activating the driven rollers of the rolling mill stand. The reducer and pinion stand can be either separate units or a single, combined unit.

Couplings connect the train’s components from the electrical motor to the mill stand and assure the transmission of power between them. In addition, they should handle torque, the misalignment between equipment, shocks, and vibrations.

Payoff and rewind reels

Strip mill lines generally include a coil process. Therefore, they have a minimum of one reel (Figure 3) to either pay off or rewind the strip. These reels go by a variety of names, including coilers, uncoilers, winders, unwinders, and tension reels.

High speed theoretical considerations

a) Tapered roller bearings – speed evaluation

The usual evaluation of the speed of a tapered roller bearing is made at the midpoint of the inner ring large rib (Figure 4). The circumferential velocity is calculated here.

The calculation formula is:

Where: Dm = mean inner ring large rib diameter in mm, n = bearing speed rev/min

This document considers a circumferential rib speed velocity of 15 m/s as the starting point of the high-speed field for tapered bearings operating on heavy-duty rolling mill auxiliary equipment. The bearings’ construction, their internal geometry, the lubricant and the lubrication system all need to be evaluated in heavy-duty/high-speed applications.

b) Spherical and Cylindrical Roller Bearings – speed evaluation

For Timken spherical roller (SRB) and cylindrical roller bearings (CRB), the thermal speed ratings are listed in the catalogue bearing tables. These values have been determined by balancing the heat generated within the bearing with the heat dissipated from the bearing.

c) High-speed operating conditions – auxiliary equipment application concerns

Today’s auxiliary equipment environments target maximum production rates. To reach this goal, the auxiliary equipment handles heavier loads and faster speeds than ever before. Bearing performance and damage become concerns in this case.

Figures 5 shows an example of a tapered roller-double outer ring (TDO) bearing damaged by cage breakage. The bearing was mounted on the high-speed input shaft of a gear drive and also was exposed to high acceleration and deceleration.

The remaining bearing components (inner and outer rings and rollers) have been placed next to the TDO in the original bearing box. Post-damage analysis shows that the bearing components are in good shape except for the cages, which are broken.

Figure 6 shows an example of a burned spherical roller bearing that operated in a high-speed gear drive.

Innovative solutions for very high-speed rolling mill auxiliary equipment

The designs traditionally used in gear drives and reels are SRB, CRB or TDO bearings. Bearing damage may manifest in these traditional bearings when operated at very high speeds in the form of burning/overheating (poor lubrication) or cage damage (unloaded rows in the case of high axial loads, high cage clearance or high mounted endplay). The Timken Company has developed two new, innovative tapered roller bearings (the 2TS-IMC and 2TSMA-IMC) to address these issues.

a) 2TS-IMC – two single rows indirect-mounted in a carrier

The 2TS-IMC bearings are designed for operating on rolling mill auxiliary equipment where the rib speed exceeds 25 m/s. The 2TS-IMC bearing assembly is made up of two single tapered roller bearings (TS=tapered roller bearing, single row). The TS bearings are indirect-mounted (IM=indirect mounting) into a carrier (C=carrier), as shown in Figure 7a. Every TS bearing’s outer rings are blocked against rotation by means of a key (Figure 7b). The carrier is keyed into the housing (Figure 7c) to prevent such rotation.

The 2TS-IMC bearing assembly has spring-loaded outer rings (Figure 7c) in order to keep the TS bearing’s rows permanently seated and to induce zero internal operational endplay. The assembly reduces cage vibration and the risk of damage. The bearing has features to accommodate a circulating oil system and a special design for improving bearing lubrication and reducing the risk of overheating. This special design involves collecting the oil flow via a lubrication groove manufactured on the outside diameter of the carrier and pointed at the roller’s small end (the area between the cage bore and the inner ring’s small rib outer diameter) through radial and axial lubrication holes (Figure 7d).

The internal geometry of the bearing’s rings and rollers is designed to reduce heat generation under very high-speed operating conditions and for mitigation of the risk of cage damage.

b) 2TSMA-IMC – two single rows with axial oil provision (MA=manifold), indirect-mounted in a carrier

At normal operating speeds, the oil is carried inside the bearing from the small end to the large end of the roller (Figure 8).

At high speeds, the lubricant begins to move outward due to centrifugal effects. Centrifugal force throws all the oil out of the cup, bypassing the roller end-rib contact area. The contact between the roller large end and the inner ring’s rib thus becomes critical because of the risk of overheating. In order to reduce this risk, the 2TSMA-IMC bearing’s construction is engineered to be effective in rolling mill auxiliary equipment where the rib speeds exceed 35 m/s.

2TSMA-IMC bearings (Figure 9a) have all the design elements of the 2TS-IMC and, in addition, feature a special component (the manifold) to ensure adequate lubrication of the critical roller large end-rib contact area and to reduce the risk of bearing overheating. The manifold is a machined piece pressed onto the inner ring outside diameter (Figure 9b). The concept works by capturing oil driven by centrifugal forces in this manifold and directing it to the critical roller large end-rib contact area through holes drilled axially in the inner ring.

Innovative high-speed coiler gear drive

A well-known aluminum company opened a new mill complex, completing the first phase of a huge modernization project. The centerpiece is a new aluminum cold rolling mill that produces the world’s widest flat-rolled aluminum strips for aerospace applications. Timken equipped the mandrel output shaft of its coiler gear drive (Figure 10). The coilers were built by a longtime Timken customer that is also one of the largest original equipment manufacturers (OEMs) in the world.

Traditional bearing designs (SRB, CRB and TDO types) cannot accommodate extreme high-speed operating conditions (maximum rib speed of 35 m/s) because of their imposed very large inner ring bore diameter (~660 mm) combined with a maximum rotational speed of 900 rpm.

The new Timken 2TSMA-IMC bearing, part number NP293620 – NP995047 (Figure 11), was designed for these precise conditions. The bearing’s internal geometry has been precisely engineered to reduce the risks of overheating and cage damage. Timken also provided lubricant specifications and lubrication system recommendations (oil features, oil flow quantity and oil jet position) for the aluminum company’s new coiler gear drive (Figure 12).

During drive operation, oil jets pump oil into the manifold area. The manifold captures the oil using centrifugal forces and directs it to the critical roller large end-rib contact area through holes drilled axially in the inner ring.

The OEM tested the coiler gear drive at maximum output speed for an hour, which meant the 2TSMA-IMC NP293620 – NP995047 bearing had to operate consistently at a rib speed of

35 m/s.

During testing, the bearing’s temperature remained constant at 80°C. Vibration levels stayed within acceptable limits, and the post-test inspection showed that the cage withstood the testing conditions well.

Summary and conclusions

Today’s rolling mill environments target maximum production rates. To reach this goal, mill auxiliary equipment handles heavier loads and faster speeds than ever before. Bearing life and damage become serious concerns.

The Timken Company provides a complete range of solutions for auxiliary equipment including bearings (ball, tapered, cylindrical and spherical), bearing-related products (housing units, lubrication and seals), power transmission equipment (couplings, gears, belts and chains) and services (bearing inspection and repair, condition monitoring systems). These solutions help assure consistent operation for rolling mill auxiliary equipment operated under heavy-duty load conditions. The innovative 2TS-IMC and 2TSMA-IMC tapered roller bearings have been developed by Timken for rolling mill auxiliary equipment operated under very high-speed conditions (rib speed over 25 m/s). The internal geometry of the bearings’ rings and rollers are designed to reduce heat generation under these conditions. These bearings have been tested on rolling mill lines and meet customers’ expectations.

The advantages of 2TS-IMC and 2TSMA-IM innovative construction versus traditional SRB, CRB or TDO designs include:

a. Ability to reach a higher speed with a high-load capability

b. Reducing the risk of bearing burning by assuring correct lubrication

c. Reducing the risk of cage damage (unloaded rows under high axial loads, high cage clearance, or high mounted endplay).

The 2TS-IMC and 2TSMA-IMC cup carrier enables the use of the same assembly on the fixed and floating shaft positions.