Increasing Power Density in Agricultural Equipment

The continuous push to improve efficiency for powered agricultural equipment is presenting agricultural OEMs with a multitude of engineering challenges. To meet tightening emissions regulations, vehicles must incorporate new, efficient technologies. Maximing power density is the solution proposed by Altra Industrial Motion to achieve increased power output for greater productivity.

by Elena Magistretti

In most cases, it is simply uneconomic for an OEM to design an entirely new combine harvester, forager or tractor platform just to accommodate a change in legislation. Vast amounts of capital and time are required to deliver a new platform that meets the latest emissions standards. This reality leaves agricultural OEMs with one option: optimise existing vehicle platforms to meet the new standards.

However, this means working within the space confines of an existing platform. With the added design complexity required to improve emissions – working within these confines becomes even more challenging.

Integrating components in a smart way

Vehicle packaging allows OEMs to efficiently incorporate components and subassemblies within an existing platform. The challenge is to achieve this optimised packaging in agricultural vehicles to free up space within the existing platform.

Optimising packaging while still accommodating after treatment systems means that components must be packaged intelligently. Jacobs Vehicle Systems, a leading brand of the Altra Industrial Motion, is a global provider of engine braking and cylinder deactivation technologies. Already a mainstay in the commercial vehicle sector, the business has designed its systems to integrate directly with the valve train of the engine. This greatly improves packaging, as the system can be incorporated during initial engine design. Maximum space efficiency is achieved, with the engine ready to be installed into the platform.

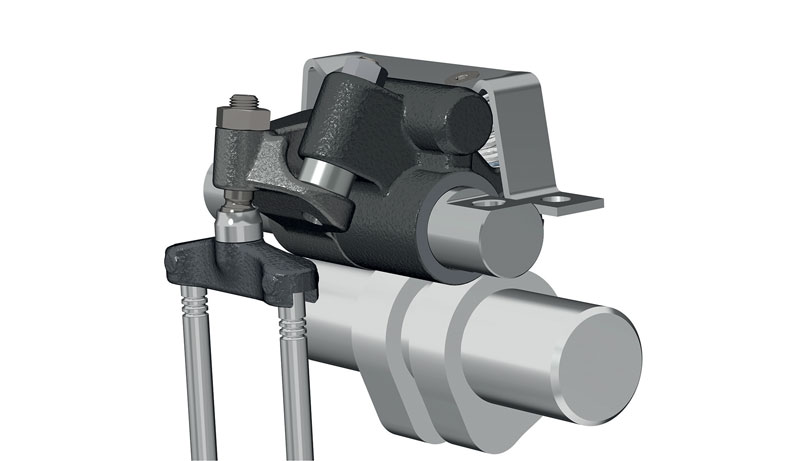

Braking systems are another area where packaging can be optimised. Warner Electric’s PK range of motor brakes combines a high friction coefficient material and a powerful coil, which optimises torque within a compact package. Suitable for parking, sudden stops and regenerative braking – it’s a highly capable solution on a small footprint that can be integrated into existing designs.

Downsizing components is crucial to free space

To accommodate new systems within an existing platform, downsizing is also crucial. Engines and power transmission components must be shrunk to free up space in the vehicle. Logic would dictate that this would come at the cost of vehicle performance, compromising horsepower output. However, this is not always the case.

Agricultural OEMs now have the ability to specify components that offer greater performance from a reduced footprint. For example, Stromag, another brand of Altra Industrial Motion, has launched its new KHE hydraulic clutch, which is compact while delivering a 20% improvement in transmittable torque.

For hybrid vehicles combining diesel and electric power trains, Stromag’s 2 in1 clutch/coupling solution offers a downsizing and damping benefit. This compact combination of an electromagnetic/hydraulic clutch combined with a flexible/dampening coupling allows for easy switching between combustion or electric power via the clutch. Clutches can be designed as multi-disc or back-lash free variants.

By specifying power transmission components that are more compact but offer increased performance, OEMs can downsize vehicle power trains effectively while still improving performance. Potential horsepower is safeguarded, while additional space for after treatment systems is secured.

Maximising power density to achieve greater productivity

By optimising packaging and downsizing components without compromising performance, agricultural OEMs can maximise power density. Increasing power density allows agricultural vehicles to enhance horsepower output within a limited size envelope. Via this approach, smaller engines can provide greater power outputs, while smaller components and subassemblies can offer improved operational performance.

Innovative power transmission components and engine systems are allowing agricultural OEMs to avoid having to design completely new platforms to balance performance and emissions legislation.

With these solutions, the power density of a vehicle can be enhanced greatly, allowing existing platforms to maximise operational potential, all the while meeting the emissions targets of the future.