Hygienic, Flexible Conveying of Food Products

Nitta, Netherland, has expanded its range of PU conveyor belts for food processing and conveying applications. Now exceeding 3 meter width, these belts are exceptionally resistant to grease, oils and chemicals; in addition they are flexible, easy to clean and have an extremely long life.

by Alma Castiglioni

Based in Osaka, Nitta Corporation is the first Japanese manufacturer of power transmission belts. Nitta has two subsidiaries in Europe: Nitta Corporation of Holland B.V. based in Alkmaar, the Netherlands, and Nitta Industries Europe GmbH based in Düsseldorf, Germany. In Alkmaar, Nitta produces high quality conveyor belts with a large portfolio of available profiles, cover materials and ply configurations with both rigid and non-rigid types of fabric. These are supplied worldwide. The focus of Nitta in Germany is on power transmission belts with a fabrication center in Altenstadt close to Frankfurt. Here, belts are stored and processed according to customer specifications.

Highly resistant to grease, oils and chemicals

For applications in the food industry, Nitta has expanded its product line of PU conveyor belts. The thermoplastic polyurethane (PU) material is exceptionally resistant to grease, oils and chemicals. The PU belts are highly flexible, easy to clean and have an extremely long life. Thanks to a unique new production machine, Nitta can now manufacture a wider range of PU belts with widths exceeding 3 m.

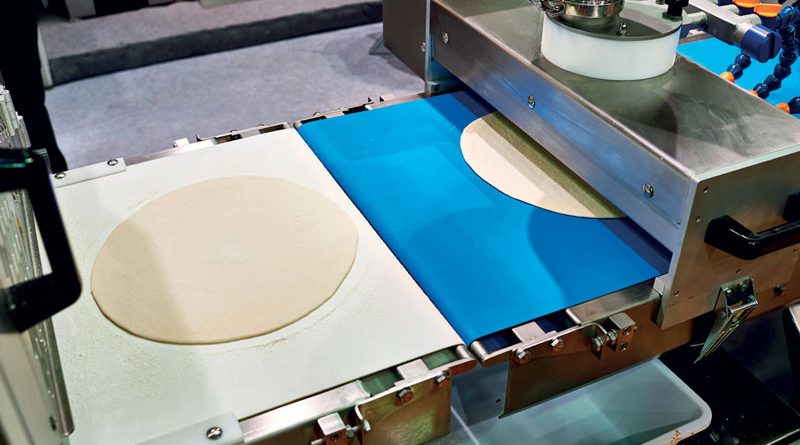

The PU conveyor belts are ideal for food processing applications such as bakeries, confectionaries, sweets and chocolates manufacturing, but also for conveying tasks in recycling, logistics, agriculture and industrial applications. In conveying food products, hygiene plays a very important role. The belt material must be chemically inert and there must be an option for fitting sealed edges. Nitta’s new thermoplastic polyurethane material excels through its exceptional resistance to grease, oils and chemicals.

Favourable properties of the new PU belts are furthermore better wear resistance and a lower coefficient of friction, which is desirable for applications with accumulated products on the belt. In selecting the belt material, colour can also be an important parameter: the food product must be clearly differentiated from the belt material in order to detect any possible contamination.

Nitta offers PU belts that meet FDA and European Union specifications in the main colours white, blue and transparent.

The constant, compact structure makes cleaning operations easier

The new machine in Nitta’s production facilities in Alkmaar in the Netherlands presses and homogenizes the cover material with calendar rollers. This results in a constant and compact structure. The homogeneous structure is a significant advantage in operation because there is less contamination and easier cleaning. The downtime of both conveyor and the production are drastically reduced and food certifications are much easier to obtain.

With the new production machine, thinner PU belts can now also be made, which means that belts can run over “knife-edges” with an even smaller diameter. For single ply belts such rollers can have diameters as small as 4 mm. These thinner belts are more flexible, have a more favourable force-elongation ratio and the increased adhesion prevents delamination of the layers. Additionally, jointing will be much easier with this material. According to Piet Vrieling, Technical Sales Manager at Nitta in Alkmaar, the market is expanding for PU belts: market trends are towards materials that contain less phthalates, that is chlorine or plasticizers. Furthermore, there is a trend towards lighter construction with smaller roller diameters in food processing as well as in logistics and warehouse distribution.