Customised solutions for agricultural equipment

Purchased in 2008 by the SKF Group, PEER Bearing is a manufacturer and supplier of bearings and units for specific sectors, mainly agriculture, where there is a strong demand for products made to measure in terms not only of the design of the bearing and its housing, but also as regards materials used, seals and lubricants. Particularly, the system which protects the bearings from external contamination is one of the most critical factors for the reliability of bearings in agricultural equipment.

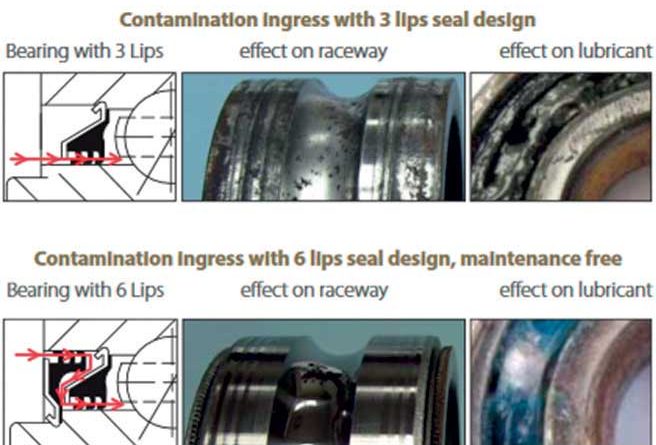

PEER developed different kinds of seals by means of a research process involving very strict lab tests so as to analyse their efficacy before their final validation on the field. An example is provided by the comparative “Mud&Slurry” tests carried out using “Arizona dust” on bearings with 3-lip and 6-lip seals; in the case of 7-lip seals it is evident that the bearing’s raceways do not show any sign of contamination and corrosion.

The definition of the number and design of the seal lips depends on the application and must reconcile the often conflicting demands of protection from external contamination and application performances, such as the bearing’s rotation speed. PEER can supply seals with up to 7 lips.

Another example of flexibility is represented by the design of the bearing, which can be strongly customised to deal with specific application demands, for instance, by developing bearings with holes or housing for profiles according to the application. This work method is today demanded by the main global manufacturers of agricultural equipment. Starting from a “blank page”, PEER may therefore design bearings or special units which satisfy the client’s demands: the suitability of the product for the application is evaluated by the engineering of the SKF application and its feasibility will then be confirmed by the Research and Development department of the factory which will have to produce it. Once the design has been approved by all the parties concerned, it is possible to create samples in a short tome and, having concluded validation, to carry on with series production even for small lots.