Competence in the Sector and Management Skills: the Keys to Tackle a Complex Project

Duplomatic MS completed an important order for the supply of hydraulic systems to a new steel mill in the Middle East. The Parabiago-based company supplied the complete package of hydraulic systems to feed continuous casting, electric furnace and ladle furnace in a new plant currently being installed. Technological competence, flexibility and ability to manage complex projects are the reasons behind the choice of Duplomatic as a supplier and the success of the project.

by Silvia Crespi

The steel industry is one of the main application sectors for Duplomatic MS. The company based in Parabiago, near Milan, is very well-known as a supplier of hydraulic components and for years now has developed a division dealing with the realization of complex systems such as, for example, high-capacity and high-power hydraulic units. Today Duplomatic MS designs and supplies hydraulic systems to the steel industry as well as to other sectors, including Energy, Plastic Injection, Oil & Gas, Machine Tools and Construction.

The growing importance of this branch of activity led to the creation of the division: Hydraulic Systems Business Unit, located in a new plant in Lainate close to the headquarters.

The mission of this BU is the design and production of hydraulic systems stemming from the identification of solutions for specific application cases.

The design and construction of a large steel mill is a complex job involving the participation of several subcontractors. For the supplier of the hydraulic system, working in synergy with each of them and knowing the context in which they operate is of paramount importance.

Duplomatic MS succeeded in interpreting these expectations thanks to a set of technological skills and field experience of the staff involved in the job order. This has been the key factor for success.

A large project with several subcontractors

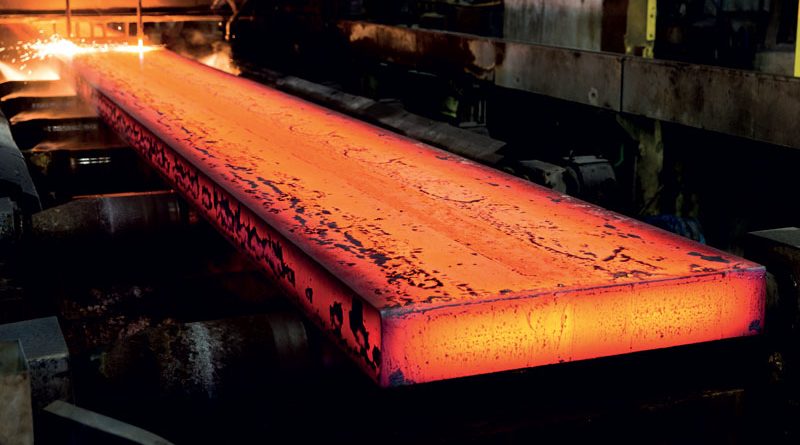

This is the case of a new and important steel mill located in the Middle East. The contract was signed in 2018 and the completion took very little time: only eight months from the signing of the contract, including the basic and detailed engineering phase. Duplomatic MS dealt with the supply of hydraulic systems for continuous casting, electric furnace and ladle furnace, the three main parts of the plant for the production of slabs.

The scope of supply consists of three large hydraulic power plants, as well as a series of small auxiliary power units for maintenance: an important order followed step by step, right from the initial stages.

As explained by Carlo Vergano, Product Manager at Duplomatic MS “in projects of this type competence not only in the hydraulic sector but also in the application sector is fundamental. The combination of these two aspects allows us to offer the most effective and appropriate solutions for each application. Clients recognize in their partner someone who understands their language and knows how to find the right solution”. In other words, this means going beyond the work of a simple subcontractor, who merely supplies equipment, and becoming a partner.

From the technical-management standpoint, besides, being aware of the purpose of the supply which makes up the entire plant, that is, the various parts which contribute to its realization, is essential to interact appropriately with other stakeholders, knowing how to anticipate their needs and what to expect from them in terms of information exchange.

In order to design the hydraulic system correctly, it is necessary to know how the mechanical part and the piping system are structured, and to know the installation sequence: only taking all this into account can the proposed hydraulic solution meet all the requirements and combine correctly with the other parts of the plant”.

The accurate analysis of the plant layout is the starting point

The starting point is the accurate analysis of the plant design, in all its parts. “We carefully studied the project, identified possible improvements with respect to the client’s initial idea – Vergano continued – and we therefore designed and built the equipment accordingly in full compliance with the project schedule.

Each of the three areas, continuous casting, electric furnace and ladle furnace has a dedicated central unit; the valve banks serve the various zones of each area. Continuous casting, for example, consists of several zones: the ingot mould, the oscillator system, the casting segments and the slab discharge zone. Each of these zones may be considered as a separate machine with its own hydraulic equipment “.

The management aspect is the real added value in this type of application

The process begins with the analysis of the process, the handling to be carried out, the performance to be achieved, the feasibility and ease of installation of the hydraulic equipment. It is necessary, for instance, to take into account the outlets of the pipes which must be compatible with the characteristics of the building, in case of floor installation, or with those of the machine itself (footprint, handling, mechanical interference and so on) in case of installation on board.

“The management aspect was the most interesting and stimulating part of the job order – Vergano concluded. An aspect that takes into account the technological requirements, the dialogue with the other subcontractors and, ultimately, the management of the documentation.

It was fundamental to provide important support to the main contractor in terms of respect of schedules, engineering quality and information flow”.