Advanced Lubrication Solutions

Combining more than 100 years of SKF and Lincoln expertise, SKF offers the industry’s most complete portfolio of innovative lubrication solutions – from manual lubricators and tools, to the most advanced centralized and automatic lubrication systems.

by Elena Magistretti

Thanks to the synergy with Lincoln, SKF is now able to offer a complete range of lubrication solutions: pumps, lubrication pinions, dosing units, filters, as well as remote monitoring units: a complete range allowing tailored dedicated solutions to be offered in multiple application fields.

Newly designed electric pump with re-fillable plastic reservoir

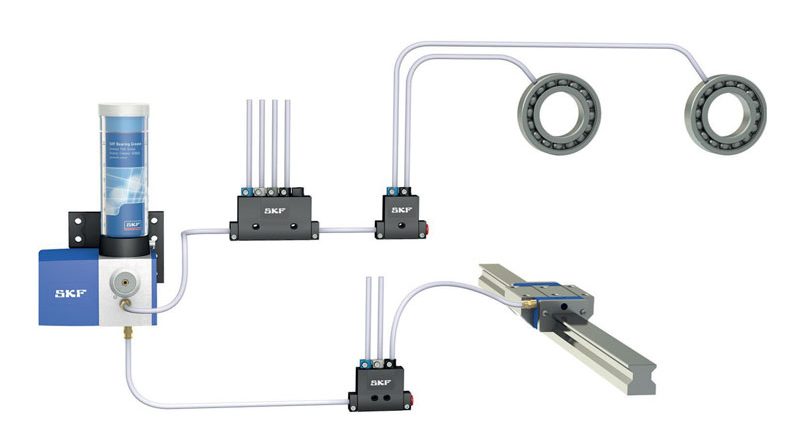

SKF’s Electric Compact Pump (ECP) for single-line lubrication systems has been updated. Originally introduced in 2016, the ECP pump is now available with both plastic reservoirs for easy refilling processes and prefilled cartridges.

The ECP is designed to lubricate bearings and linear guides with oil or fluid grease in systems of up to 20 lubrication points and a main line length of 15 meters. It includes an integrated pressure-relief valve, which enables its use in automatic SKF single-line lubrication systems. The ECP is available with prefilled lubricant cartridges or with plastic reservoirs for oil or fluid grease in three sizes. Oil reservoirs come with standard filters. The pump versions with reservoir capacities of 1,0 and 1,7 litres can be equipped with a fill-level monitor.

To eliminate the risk of lubricant contamination, SKF recommends the ECP version that utilizes the 380 ml cartridges. These easy-to-exchange cartridges are available with an optional, integrated level switch to monitor the fill level. The standard cartridge is pre-filled with fluid grease type 00. Setting new standards in design and flexibility the ECP is a cost-effective and simple-to-operate lubrication solution that works perfectly together with SKF single-line metering devices in small to medium-sized machinery.

Lubrication pinion for open gear wheels and gear racks

Another lubrication solution addressed to power transmission systems is Lincoln lubrication pinion LP2 for open gear wheels and gear racks. Complementing SKF’s existing lubrication pinion line, the reliable LP2 features a modular design and the capability to lubricate fast-rotating applications up to 80 r/min. As the lubrication pinion LP2 does not require pressurized air, there is no spray mist to contaminate the environment. Also, higher-viscosity lubricants, such as NLGI grade 2 grease, can be applied. When compared to manual lubrication, use of LP2 pinions provides better quality lubrication and reduces costs, labour and the risk of accidents.

The modular design enables customers to configure the lubrication pinion to meet specific application requirements. The LP2 is suitable for wind, mining, construction, marine and material handling applications, as well as slewing or pitch bearings.

Compact metering device for single-line lubrication systems

Lincoln SLC metering device for grease was developed for use in single-line lubrication systems, this compact metering device features a compact and modular design for less jointing and decreased risk of leaking.

Featuring a spring-reset control piston, the metering device has a high venting capability for compatibility with greases up to NLGI 2. The device provides reliable operation in harsh conditions and low temperatures. Delivery volume can be either adjusted via regulating screws or set with dosing screws, both options ensure each lubrication point receives the required amount of lubricant.

The SLC is available in two versions – the SLC1 for one to 12 outlets and the SLC2 for one to six outlets. Both are offered with BSP or NPT threads and in C3 corrosion classification. Metric and imperial sizes are included for inlet and outlet fittings.

With the most compact construction in its class, the SLC is suitable for use in renewable energy, construction and mining applications, as well as when replacing smaller, mid-pressure, dual-line lubrication systems.

Remote monitor for automatic lubrication systems

The LRM2 lubrication remote monitor is compatible with oil or grease, the monitor is designed for use with lubrication systems that cannot be checked daily due to the nature or position of the application.

The LRM2 can be used on single-line, dual-line and progressive lubrication systems and can communicate with a pump or group of pumps on a system of the same type.

The monitor utilizes a SIM card similar to those found in cell phones to send and receive text messages via iOS or android mobile devices or via e-mail to a computer.

Featuring two digital inputs and outputs, the LRM2 sends both low-level and fault messages.

The monitor can be used to start an additional lubrication cycle and can be reset simply by sending a message from a mobile device or computer. In addition, no special software is required as system information can be accessed using a web browser.

The LRM2 is suitable for wind energy, railroad wayside, cable car and wastewater treatment applications, as well as other industries. Also, the LRM2 module is available without an enclosure for applications that require mounting in an existing control box.

New grease filling filter for automatic lubrication systems

Lincoln small grease reservoir filling filter is art of SKF’s family of filtration products. This filter minimizes contaminants entering automatic lubrication systems during the filling process of smaller-sized reservoirs. Installed as an inline component in the reservoir’s fill line, the filling filter helps to ensure that clean grease enters the reservoir and the system. As grease enters through the inlet, it passes through the filter and then exits into a hose that is connected to the grease reservoir’s fill port. As the filter element becomes clogged, the unit’s clogged-indicator pin starts to retract, signaling that filter element cleaning is required. If the clogged filter element is not cleaned, grease will vent safely to a catch container but will not bypass to the reservoir. The easy-to-install Lincoln small grease reservoir filling filter is available with either a 250- or 500-micron, crush-proof filter element, which is simple to clean. It has a fill rate of up to 8 liters/min (2 gal/min, depending on application, type of grease and ambient temperature) and operating pressure of 344 bar (5,000 psi). The filter’s compact size makes remote mounting from the reservoir possible. The Lincoln small grease reservoir filling filter is suitable for off-road construction, small mining equipment, general industry, wind energy, over-the-road trucking, construction and agricultural applications.